在20世纪80年代由欧洲研制成功并开始使用。它是将熔结环氧粉末(FBE)良好的防腐蚀性能、黏结性、 高抗阴极剥离性和聚烯烃材料的高抗渗性、良好的机械性能和抗土壤应力等性能结合起来的防腐蚀结构, 其应用呈不断 上升趋势。

传统的“二 步法"制造防腐保温管中目前存在的以下弊端:由于传统"二步法"生产工艺采用的是密封空间发泡形成钢管 与PE保护夹克层之间的保温层,其泡沫发泡时的压力很大,所以必须采用很厚的PE夹克保护层, 浪费了大量的PE材料;“二步法”制作的防腐保温管,泡沫保温层与PE夹克保护层不粘接;制作工艺不连续,聚氨酯泡沫发泡密度太大,浪费材料又使保温效果降低;聚氨酯发泡是形成的保温层其密度不均匀。而另一种传统保温管制作工艺“一步法泡沫夹克保温管作业线"存在不足, 如:在“一步法”PE包覆成型时,需要更换多种机头模具对不同的钢管进行包覆成型;保温管一步法制作 工艺只能对φ529mm以下管径进行防腐保温处理,无法对更大管径钢管道进行处理。

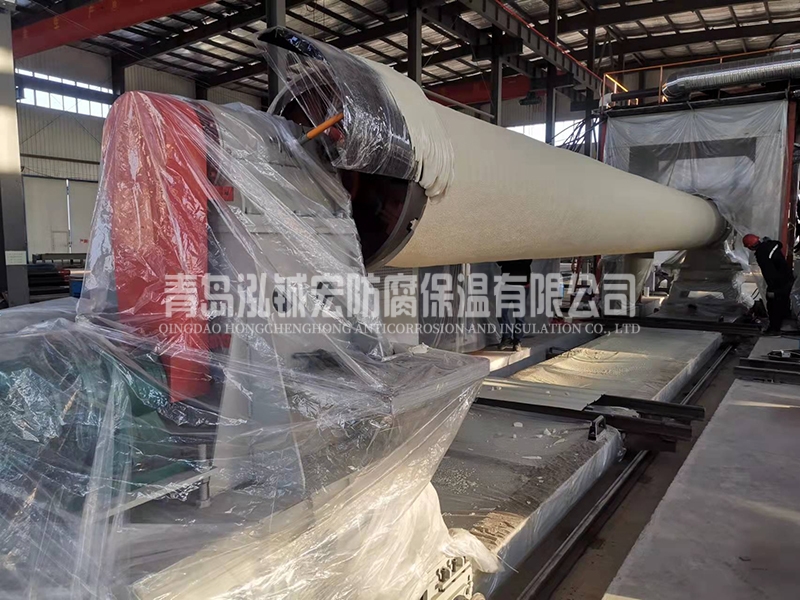

Pipeline transportation, as a safe and economical transportation method for transporting large amounts of fluid media such as oil, water, gas, etc., has a history of over 100 years in the world in the field of PE winding spray foaming equipment anti-corrosion and insulation operation line technology. However, the corrosion problem of pipelines is a key factor affecting the reliability and service life of pipeline systems. Although pipeline anti-corrosion technology has developed rapidly, there is still a significant gap compared to developed countries. With the adjustment of China's energy policies, the construction of long-distance pipelines is reaching a climax, posing new requirements for pipeline anti-corrosion and insulation.

It was successfully developed and put into use in Europe in the 1980s. It is an anti-corrosion structure that combines the excellent anti-corrosion performance, adhesion, high cathodic stripping resistance of fusion bonded epoxy powder (FBE) with the high impermeability, good mechanical properties, and soil stress resistance of polyolefin materials. Its application is constantly increasing.

The following disadvantages exist in the traditional "two-step method" of manufacturing anti-corrosion insulation pipes: because the traditional "two-step method" of production process uses sealed space foaming to form the insulation layer between the steel pipe and the PE protective jacket layer, the pressure of foam foaming is very high, so a very thick PE jacket protective layer must be used, which wastes a lot of PE materials; "two-step method" The anti-corrosion insulation pipe made of foam insulation layer is not bonded with the protective layer of PE jacket; The production process is discontinuous, the polyurethane foam foaming density is too large, and the waste of materials reduces the insulation effect; Polyurethane foam is an insulation layer formed with uneven density. The other traditional production process of insulated pipes, "one-step foam jacket insulated pipe production line", has shortcomings, such as: when "one-step" PE coating molding, it needs to replace a variety of die heads to cover different steel pipes; one-step production process of insulated pipes can only φ For pipes with diameters below 529mm, anti-corrosion and insulation treatment cannot be carried out on steel pipes with larger diameters.

With the adjustment of China's energy policies, the construction of long-distance pipelines will soon reach a climax in China, and anti-corrosion technology is also constantly improving. A series of innovations have been made in anti-corrosion and insulation technology to meet current needs.