3PE防腐设备生产线

钢管外壁3PE防腐生产线的用途

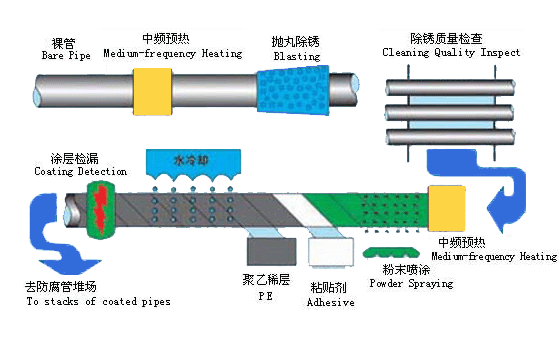

生产线是连续性的对钢管外表面经中频加热、环氧粉末喷涂(FBE)、胶粘剂缠绕(AD)、聚乙烯缠绕(PE)、水冷却、管端打磨等工序,生产出合格的3PE防腐管。

3PE防腐执行标准:

SY/T0413-2002埋地钢质管道聚乙烯防腐层技术标准

国标GB/T23257-2017

DIN30678《钢管管道聚烯涂层》

FBE环氧粉末防腐执行SY/TO315-1997《钢制管道熔化环氧涂料技术标准》

外防(3PE)生产线工艺描述:

涂敷输送线主段接近环氧粉末喷涂设备处安装有中频加热器。该设备可将钢管外表面加热到环氧粉末喷涂所需的温度(150℃~250℃)。加热后的钢管穿过安装在输送线上的环氧粉末喷涂室,安装在喷涂室内的高压静电喷枪喷出的环氧粉末均匀地吸附在热的钢管外表面,并迅速熔结成一层厚度均匀的涂层。环氧粉末喷涂室和涂敷区的距离应保证涂敷在粉末的胶化过程中进行。喷涂上环氧粉末的钢管在粉末的胶化过程中。胶粘剂挤出机和聚乙烯挤出机将物料均匀地呈薄片状挤出,依次把胶粘剂和聚乙烯缠绕钢管上。胶粘剂和聚乙烯颗粒通过负压抽吸式集中供料系统供给,在整个生产过程中,胶粘剂和聚乙烯的供应是不间断的。

旋转前进的钢管带动胶粘剂和聚乙烯薄片经硅胶压辊压实在钢管外表面上。涂敷完毕后的钢管要立刻进行水冷却以降低其温度,避免热的防腐层在传送过程中受损伤。水冷却室内的前组辊道的间距较小,以减小热的防腐层所受的压力,保证焊缝处的防腐层厚度。热交换后的水经冷却塔散热后循环使用。

防腐管到达涂敷输送线的尽头,然后翻上检验平台对防腐层进行检验。检验后的防腐管要经管端处理装置,清除掉管端焊接区的防腐层,已达到标准要求。管端打磨干净的合格防腐管喷上标记生产结束。

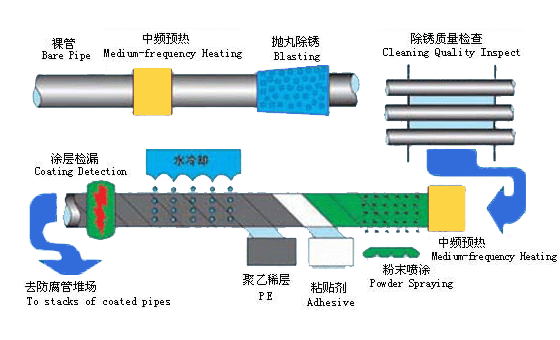

3PE工艺流程示意图

3PE anti-corrosion equipment production line

Application of 3PE anti-corrosion production line for steel pipe outer wall

The production line is a continuous process that involves heating the outer surface of steel pipes with medium frequency, epoxy powder spraying (FBE), adhesive winding (AD), polyethylene winding (PE), water cooling, and pipe end polishing to produce qualified 3PE anti-corrosion pipes.

3PE anti-corrosion execution standard:

SY/T0413-2002 Technical Standard for Polyethylene Anticorrosive Coatings on Buried Steel Pipelines

GB/T23257-2017

DIN30678 "Polyene Coatings for Steel Pipe and Pipeline"

FBE epoxy powder anti-corrosion shall comply with SY/TO315-1997 "Technical Standard for Melting Epoxy Coatings on Steel Pipelines"

Process description of external defense (3PE) production line:

A medium frequency heater is installed near the epoxy powder spraying equipment in the main section of the coating conveyor line. This equipment can heat the outer surface of the steel pipe to the temperature required for epoxy powder spraying (150 ℃~250 ℃). The heated steel pipe passes through the epoxy powder spraying room installed on the conveyor line. The epoxy powder sprayed by the high-voltage electrostatic spray gun installed in the spraying room is evenly adsorbed on the outer surface of the hot steel pipe and quickly melted into a layer of uniform thickness coating. The distance between the epoxy powder spraying room and the coating area should ensure that the coating is carried out during the powder gelation process. Steel pipes coated with epoxy powder are subjected to the gelation process of the powder. The adhesive extruder and polyethylene extruder evenly extrude the material in a thin sheet shape, and sequentially wrap the adhesive and polyethylene onto the steel pipe. The adhesive and polyethylene particles are supplied through a negative pressure suction centralized feeding system, and the supply of adhesive and polyethylene is uninterrupted throughout the entire production process.

The rotating steel pipe drives the adhesive and polyethylene sheet to be compacted on the outer surface of the steel pipe through a silicone roller. After coating, the steel pipe should be immediately cooled with water to reduce its temperature and avoid damage to the hot anti-corrosion layer during transportation. The spacing between the front roller tracks in the water cooling room is small to reduce the pressure on the hot anti-corrosion layer and ensure the thickness of the anti-corrosion layer at the weld seam. The water after heat exchange is circulated for use after being dissipated by a cooling tower.

The anti-corrosion pipe reaches the end of the coating conveyor line, and then turns over the inspection platform to inspect the anti-corrosion layer. After inspection, the anti-corrosion pipe should be treated with a pipe end treatment device to remove the anti-corrosion layer from the welding area of the pipe end, which has met the standard requirements. The qualified anti-corrosion pipe with polished and clean pipe ends shall be marked with the end of production.

Schematic diagram of 3PE process flow

上一个:没有了

下一个:PE缠绕喷涂发泡设备

地址:山东省青岛市胶州市胶北街道北关工业园山东道36号

网址:www.hchff.com

手机:15192760888 13708952663